Understanding Real-Time OEE Monitoring

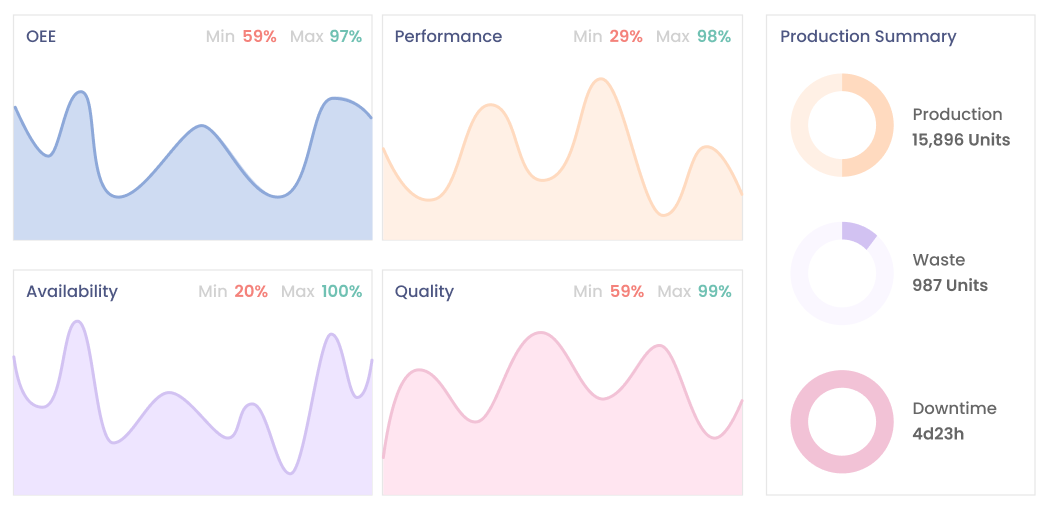

To harness the full potential of Real-Time OEE monitoring, production managers must first grasp its fundamental concepts and functionalities. Real-Time OEE monitoring involves the continuous tracking and analysis of three key metrics: availability, performance, and quality. These metrics provide a holistic view of equipment effectiveness and operational performance in real-time, enabling production managers to identify bottlenecks, inefficiencies, and opportunities for improvement on the shop floor.

Availability refers to the percentage of time that equipment is available for production during scheduled production time. It accounts for downtime, including planned stops for maintenance, as well as unplanned stops due to breakdowns or other issues. Performance measures the speed at which equipment operates relative to its maximum speed, taking into account factors such as equipment slowdowns, idling, and minor stoppages. Quality assesses the rate of production of good-quality products relative to total production output, accounting for defects, rework, and scrap

By continuously monitoring these metrics in real-time, production managers gain valuable insights into equipment performance, utilization, and overall efficiency. Real-Time OEE monitoring systems collect data from sensors, machines, and production lines, aggregating it into actionable insights presented through intuitive dashboards and reports. These insights enable production managers to quickly identify production issues, prioritize corrective actions, and make data-driven decisions to optimize performance and maximize output.

Moreover, Real-Time OEE monitoring facilitates proactive maintenance practices by providing early warnings of equipment malfunctions or degradation. By detecting potential issues before they escalate into costly breakdowns, production managers can schedule preventive maintenance activities strategically, minimizing downtime and optimizing equipment uptime. This proactive approach to maintenance not only enhances equipment reliability and longevity but also contributes to overall operational efficiency and cost savings.

Implementing Real-Time OEE Monitoring

Implementing Real-Time OEE monitoring requires careful planning, execution, and integration with existing systems and processes. To ensure successful implementation, production managers must adhere to best practices and consider various factors to maximize the effectiveness of Real-Time OEE monitoring in their manufacturing operations.

First and foremost, production managers should define clear objectives and goals for implementing Real-Time OEE monitoring. Whether the focus is on reducing downtime, increasing productivity, improving quality, or all of the above, establishing specific, measurable, achievable, relevant, and time-bound (SMART) goals provides a clear roadmap for implementation and helps measure the success of the initiative.

Next, production managers need to select the right Real-Time OEE monitoring solution that aligns with their operational requirements, budget constraints, and technological infrastructure. The chosen solution should offer robust functionality, scalability, and ease of integration with existing equipment, software systems, and data sources. Additionally, it should provide intuitive user interfaces, customizable dashboards, and real-time alerts to facilitate proactive decision-making and problem-solving on the shop floor.

Furthermore, training and change management are critical aspects of successful implementation. Production managers should ensure that employees, from operators to supervisors, are trained on how to use the Real-Time OEE monitoring system effectively and understand its importance in driving operational improvements. Additionally, fostering a culture of data-driven decision-making and continuous improvement is essential for maximizing the impact of Real-Time OEE monitoring across the organization.

Integration with other manufacturing systems and processes is another key consideration. Real-Time OEE monitoring systems should seamlessly integrate with enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and other relevant software applications to enable data sharing, streamline workflows, and facilitate cross-functional collaboration.

Moreover, production managers should establish key performance indicators (KPIs) and metrics to track the effectiveness of Real-Time OEE monitoring implementation over time. Regular performance reviews and evaluations help identify areas for refinement, optimization, and expansion of Real-Time OEE monitoring capabilities to drive ongoing improvements in manufacturing operations.

Smart View of OEE Monitoring

Real-Time OEE Monitoring in Action

To illustrate the practical application and benefits of Real-Time OEE monitoring, examining real-world case studies and success stories provides valuable insights into its transformative impact on manufacturing operations

- Example 1: Automotive Manufacturing Company

An automotive manufacturing company implemented Real-Time OEE monitoring to improve production efficiency and reduce downtime on its assembly lines. By tracking availability, performance, and quality metrics in real-time, the company identified bottlenecks and inefficiencies in the production process. With actionable insights from the monitoring system, the company optimized equipment utilization, streamlined production workflows, and minimized unplanned downtime. As a result, the company achieved a significant increase in productivity, reduced production costs, and enhanced overall equipment effectiveness. - Example 2: Food and Beverage Manufacturer

A food and beverage manufacturer adopted Real-Time OEE monitoring to enhance quality control and ensure compliance with regulatory standards. By monitoring quality metrics in real-time, the company detected deviations from quality standards and identified potential issues with production equipment. With timely interventions based on real-time data insights, the company improved product quality, reduced waste, and enhanced customer satisfaction. Additionally, the company achieved greater visibility and traceability across its production processes, enabling faster problem resolution and improved regulatory compliance. - Example 3: Electronics Manufacturing Facility

An electronics manufacturing facility implemented Real-Time OEE monitoring to optimize production line performance and increase throughput. By continuously monitoring equipment availability, performance, and quality in real-time, the facility identified opportunities for process optimization and efficiency improvements. Through proactive maintenance interventions and performance optimizations guided by real-time data insights, the facility achieved a significant reduction in downtime, improved overall equipment effectiveness, and increased production output. The implementation of Real-Time OEE monitoring transformed the facility's manufacturing operations, driving substantial cost savings and enhancing competitiveness in the market

Overcoming Challenges and Maximizing Benefits

While Real-Time OEE monitoring offers numerous benefits for manufacturing operations, implementing and leveraging this technology effectively may pose certain challenges. Understanding these challenges and implementing strategies to overcome them is crucial for maximizing the benefits of Real-Time OEE monitoring in manufacturing environments.

One common challenge is data integration and connectivity. Manufacturing facilities often have diverse equipment and systems that generate data in different formats and protocols. Integrating data from these disparate sources into a unified Real-Time OEE monitoring system can be complex and time-consuming. To address this challenge, manufacturers can invest in interoperable technologies, standardized data protocols, and middleware solutions that facilitate seamless data integration across the manufacturing ecosystem.

Another challenge is ensuring data accuracy and reliability. Inaccurate or incomplete data can lead to erroneous insights and decisions, undermining the effectiveness of Real-Time OEE monitoring. Manufacturers must implement robust data collection processes, validate data accuracy through regular audits and validations, and invest in sensor technologies and equipment monitoring systems to ensure reliable data capture in real-time.

Moreover, resistance to change and lack of buy-in from stakeholders can hinder the successful implementation of Real-Time OEE monitoring initiatives. To overcome resistance and foster organizational buy-in, manufacturers should emphasize the benefits of Real-Time OEE monitoring, provide comprehensive training and support to employees, and involve key stakeholders in the decision-making process from the outset. Demonstrating tangible results and successes through pilot projects can also help build momentum and support for broader adoption of Real-Time OEE monitoring initiatives.

Additionally, maintaining cybersecurity and data privacy is paramount when implementing Real-Time OEE monitoring systems, as they involve collecting and analyzing sensitive production data in real-time. Manufacturers must implement robust cybersecurity measures, such as encryption, access controls, and network segmentation, to protect data integrity and confidentiality. Regular security assessments and audits can help identify vulnerabilities and mitigate risks associated with Real-Time OEE monitoring systems.

Despite these challenges, manufacturers can maximize the benefits of Real-Time OEE monitoring by implementing comprehensive strategies and best practices. By addressing data integration, accuracy, stakeholder buy-in, cybersecurity, and other key considerations, manufacturers can overcome challenges and unlock the full potential of Real-Time OEE monitoring to drive operational excellence, efficiency, and competitiveness in today's dynamic manufacturing landscape.

Future Trends and Innovations in Real-Time OEE Monitoring

As manufacturing technology continues to evolve, so too does the landscape of Real-Time OEE monitoring. Looking ahead, several trends and innovations are poised to shape the future of Real-Time OEE monitoring and revolutionize manufacturing operations.

One emerging trend is the integration of artificial intelligence (AI) and machine learning (ML) technologies into Real-Time OEE monitoring systems. AI and ML algorithms can analyze vast amounts of production data in real-time, uncovering hidden patterns, predicting equipment failures, and providing actionable insights for process optimization. By harnessing the power of AI and ML, manufacturers can enhance predictive maintenance capabilities, optimize production scheduling, and improve overall equipment effectiveness.

Another trend is the rise of edge computing and edge analytics in Real-Time OEE monitoring. Edge computing involves processing and analyzing data locally at the source, such as on the manufacturing shop floor, rather than relying solely on centralized cloud-based systems. This enables faster data processing, reduced latency, and real-time decision-making, making it ideal for applications like Real-Time OEE monitoring where immediate insights are critical for operational efficiency.

Furthermore, the adoption of Industrial Internet of Things (IIoT) devices and sensor technologies is driving advancements in Real-Time OEE monitoring. IIoT devices, such as smart sensors and connected machinery, collect real-time data on equipment performance, environmental conditions, and production metrics. By leveraging IIoT data streams, manufacturers can gain deeper insights into their operations, improve equipment reliability, and optimize production processes for maximum efficiency.

Additionally, the concept of digital twins is gaining traction in Real-Time OEE monitoring. A digital twin is a virtual replica of a physical asset or system that enables real-time monitoring, simulation, and analysis of its behavior and performance. By creating digital twins of production equipment and processes, manufacturers can simulate different scenarios, predict outcomes, and optimize operations in real-time, leading to improved overall equipment effectiveness and operational efficiency.

Moreover, advancements in cloud computing and data analytics technologies are enabling manufacturers to leverage Real-Time OEE monitoring as a service. Cloud-based Real-Time OEE monitoring platforms offer scalability, flexibility, and accessibility, allowing manufacturers to access real-time insights from anywhere, anytime, and on any device. This shift towards cloud-based solutions democratizes access to Real-Time OEE monitoring capabilities, making it more accessible to manufacturers of all sizes.

Workers enjoying after completing the shift with easy OEE calculation

Conclusion

Real-Time Overall Equipment Effectiveness (OEE) monitoring stands as a vital tool for production managers aiming for smarter manufacturing. Offering unparalleled visibility and insights, it enables proactive decision-making, minimizes downtime, and maximizes productivity. Implementing Real-Time OEE monitoring requires careful planning, training, and integration with existing systems. Despite challenges, trends like AI, edge computing, and IIoT promise to shape its future, unlocking new levels of operational excellence in manufacturing. In summary, Real-Time OEE monitoring is the cornerstone of smarter manufacturing, driving continuous improvement and excellence in the dynamic manufacturing landscape.